Top Ball Screw for Sale Options in 2026 What to Look For?

In 2026, the market for ball screw for sale is evolving rapidly. Buyers have many options, but not all are equal. Quality and performance are key. It’s essential to consider various factors when evaluating potential purchases.

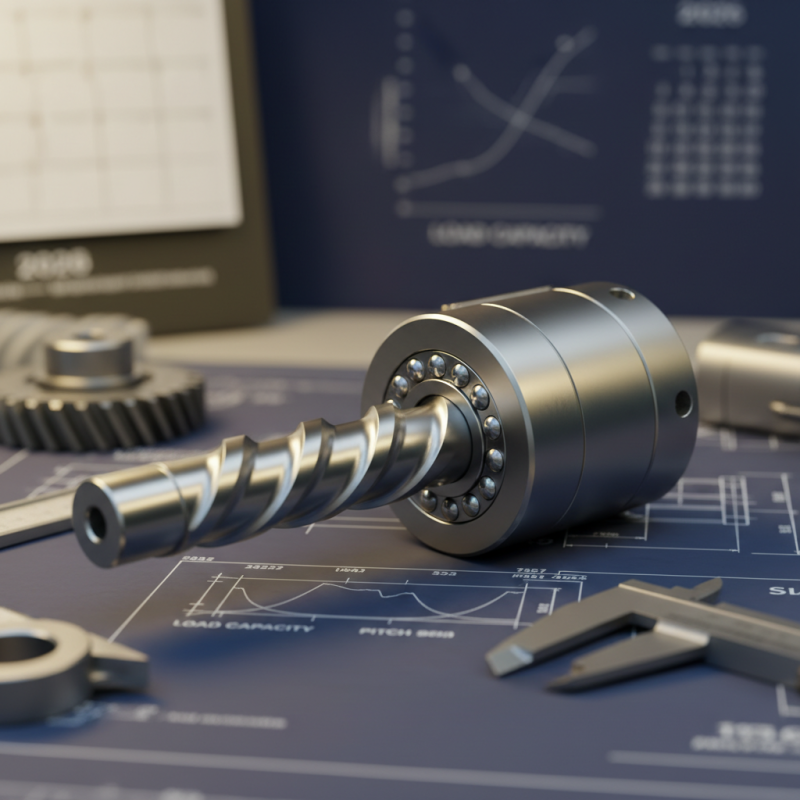

Understanding the specifications is crucial. Look for screw diameter, pitch, and load capacity. These details will impact your project’s efficiency. Some suppliers focus on cost, but lower prices often lead to compromised quality. Make sure to assess reliability and service life.

Choosing the right ball screw for sale demands careful thought. It's tempting to rush the decision. However, a hasty choice may result in poor performance or increased costs later. Consult with professionals and gather insights. There’s no substitute for thorough research.

Top Factors Influencing Ball Screw Selection in 2026

Choosing the right ball screw in 2026 involves several key factors. Precision is crucial. Reports indicate that around 70% of manufacturers prioritize accuracy in their machinery. The slightest deviation can lead to significant production issues. Ball screws with a tolerance of ±0.01 mm are becoming a standard expectation.

Load capacity is another vital consideration. Many companies seek designs that can handle increased weight while maintaining efficiency. Data shows that ball screws with a load rating over 25,000 N are preferred for heavy-duty applications. This shift illustrates the need for robustness in modern engineering.

Additionally, environmental impact is gaining traction. Sustainability reports highlight that 60% of engineers look for components that minimize energy consumption. Increasingly efficient designs not only reduce carbon footprints but also cut operational costs. Potential buyers should assess energy ratings and choose options that align with these criteria. However, not all products transparently provide this information, making it challenging for decision-makers to find suitable solutions.

Top Ball Screw Selection Factors in 2026

Market Trends and Innovations in Ball Screw Technologies for 2026

As we move into 2026, the ball screw market is witnessing notable innovations. Manufacturers are increasingly adopting advanced materials. These new materials enhance durability while reducing weight. Consequently, machines become more efficient in their operations. This shift is crucial for various industries like automation and aerospace.

Another significant trend is the integration of smart technologies. Sensors embedded in ball screws provide real-time data. This innovation allows for predictive maintenance, minimizing downtime. In addition, the demand for custom solutions continues to rise. Companies are looking for specific configurations to meet unique needs. This customization trend creates challenges for manufacturers. They must balance mass production with tailored solutions.

Sustainability is also taking center stage. Eco-friendly manufacturing processes are becoming essential. Companies face pressure to reduce their carbon footprint. However, implementing these practices can complicate production. There is still a long way to go for complete sustainability. The ball screw industry must continue to adapt to these evolving demands while addressing its shortcomings. Remember, the future lies in innovation and reflection on existing practices.

Key Performance Metrics for Evaluating Ball Screws in Engineering Applications

When evaluating ball screws for engineering applications, various performance metrics come into play. Load capacity is essential. It tells you how much weight the screw can handle. A higher load means better durability. Speed is also crucial. It focuses on how fast the ball screw can operate while maintaining accuracy. Testing this under real conditions is vital.

Precision is another key factor. A small error can result in significant issues in machine operations. Look for a ball screw with tight tolerances. Life expectancy matters too. You want components that last. Check wear rates and maintenance needs. Balancing these metrics can be tricky. Sometimes, a screw that seems ideal on paper fails in practice.

Heat generation is worth considering. It can affect performance and lifespan. Monitor how a screw performs under continuous use. Efficiency is vital for energy savings. A more efficient screw saves costs in the long run. Evaluating these metrics is not straightforward. It requires thought and sometimes a bit of trial and error. Finding the right balance is critical for success in engineering applications.

Cost Analysis: Comparing Ball Screw Options in 2026 Market

In 2026, the ball screw market presents a variety of choices. Understanding cost factors is crucial. Recent industry reports indicate that material quality significantly influences pricing. For instance, high-grade stainless steel screws may cost up to 30% more than standard alloy options. This premium often translates to enhanced durability and performance.

When comparing options, consider both initial costs and long-term value. Some manufacturers offer low-priced screws, but these could require more frequent replacements. This can lead to higher costs over time. Experts recommend analyzing the total cost of ownership rather than just the purchase price.

Another aspect to reflect on is the service and support offered with the purchase. A lower price might come with limited customer assistance. A gap in support could lead to delays in production or maintenance challenges. Balancing price with service is essential. In the dynamic landscape of 2026, making informed decisions will help you avoid costly pitfalls.

Best Manufacturers and Suppliers of Ball Screws to Consider in 2026

When selecting ball screws, consider various factors to ensure the best choice. The manufacturing process is crucial. Look for companies that prioritize precision and quality. This impacts overall performance. A reliable supplier should provide detailed specifications.

Tip: Always ask for samples. Testing a sample can reveal a lot. It helps you gauge if the product meets your standards. Many manufacturers focus on technical support. This is vital for troubleshooting later on. Don't underestimate the importance of customer service.

In 2026, sustainability matters too. Seek out manufacturers that use eco-friendly materials. This approach can enhance your brand's reputation. However, remember at times, the cheaper option may not be the best. Quality should not be compromised for cost. Reflect on your needs carefully before making a decision.